Newest

-

CYCJET: Providing innovative marking solutions for industrial intelligence along the Belt and Road Initiative.

-

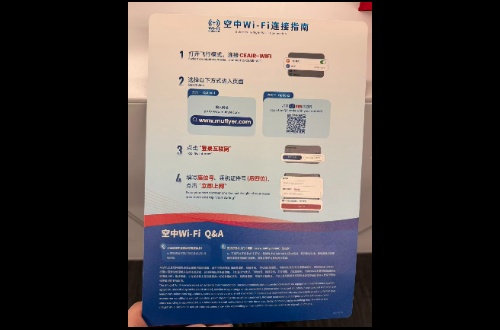

Celebrating in the Sky: China Eastern Airlines to Offer Free In-Flight Wi-Fi as Part of Chinese New Year Connectivity Upgrade

-

China Eastern Airlines Unveils Top International and Regional Destinations as Chinese New Year Travel Peaks

-

MEXC COO Vugar Usi on Navigating Crypto's 2026 Reset: Why Retail-First Exchanges Are Winning

Well spacing of CO2 flooding in low-permeability reservoir of Shengli Oilfield

2021-12-13

2021-12-13

LI Jinzhi1

1. Oil and Gas Development Management Center, Shengli Oilfield Company, SINOPEC, Dongying 257001, Shandong Province, China

Abstract: Considering the complexity of optimizing well spacing with component numerical simulation and the insufficiency of capturing reservoir heterogeneity and crude-oil viscosity changing with space in CO2 flooding with conventional calculation methods of critical well spacing, the relationship between the threshold pressure gradient (TPG) and the air permeability of low-permeability reservoirs in Shengli Oilfield is obtained by regression through a large number of laboratory experiments. Based on the non-Darcy flow theory and considering the reservoir heterogeneity, the reduced viscosity of crude oil by CO2 flooding, convection, diffusion, and adsorption, a mathematical model of injector–producer pressure difference of line well pattern in CO2miscible flooding is established, and the methods for determining the critical flow well spacing and the reasonable production-well spacing are proposed. With a low-permeability reservoir in Shengli Oilfield taken as an example, the critical flow well spacing for CO2 miscible flooding is calculated. The results indicate that when the permeability increases to a certain value, the TPG stably decreases with the growth of permeability. When the apparent permeability decreases to a certain value, the TPG soars with the decline in permeability. For the low-permeability reservoirs in Shengli Oilfield, with the increase in the injector–producer pressure difference, the reasonable production-well spacing gradually rises, and the calculated reasonable production-well spacing is consistent with the actual injector–producer spacing, which verifies the reliability of the calculation method in this paper.